On May 20, 2018, technicians from Juli Adhesive Manufacturer visited new and old customers under the scorching sun. Coincidentally, a metal products factory was facing the trouble that the bonding of small-area metals was neither fast enough nor firm. The technicians conducted an on-site test with the samples of the metal-specific instant adhesive they carried. They bonded various materials such as iron, stainless steel, and aluminum in small areas. The positioning time was only 8 to 10 seconds, and the practical strength could be achieved half an hour later. Factory Director Liu immediately decided to use Juli Brand Metal-specific Instant Adhesive in production and stopped using the previous adhesive.

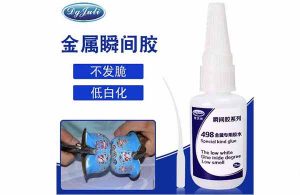

Juli Brand JL-498 Metal-specific Instant Adhesive,It is a special instant adhesive for bonding small areas of metal to metal. Its adhesive performance is excellent, making it suitable for bonding small areas between various types of metal materials. It is a high-strength single-component instant adhesive, specifically designed for the high-strength bonding requirements of various metals such as iron, copper, stainless steel, lead, aluminum, and synthetic metals. The positioning time is only 8 to 10 seconds, and practical strength can be achieved half an hour later, which is highly suitable for continuous production line operations. It meets international environmental protection standards and has passed the EU ROHS standard and SGS testing.

If you choose Juli Brand Metal-specific Instant Adhesive, you can easily solve problems such as easy whitening during metal bonding, unattractive appearance, and insufficient bonding strength. Moreover, Juli Company provides excellent after-sales service, always putting the interests of customers first and doing its best to meet their needs. We look forward to reaching a long-term cooperation agreement with you.

JL-498 Special Instant Adhesive for Metals The JL-498 Special Instant Adhesive for Metals is a single-component instant adhesive designed for the high strength required in small-area metal bonding. It is specifically tailored for the high-strength bonding of various metals like iron, copper, stainless steel, lead, aluminum, and synthetic metals to each other.

The main component of Juli Brand’s JL-498 Special Instant Adhesive for Metals is cyanoacrylate. It complies with environmental protection standards and has passed the EU ROHS standard and SGS testing. The base is methyl cyanoacrylate. The methyl series is a single-component instant adhesive designed for the high strength needed in small-area metal bonding. It possesses excellent properties such as high performance, high strength, being a single component, and resistance to aging. It is highly suitable for continuous production line operations.

Technical Parameters

viscosity (mpa.s) 1500-2000

Fill the gap (mm) 0.2~0.5

Tensile strength (kg/cm2) 240

Shear strength (Mpa) 23

Curing speed (s) 5-10s

Temperature range (℃) -40±120

Among the adhesives that can replace welding, AB adhesives are the most commonly used. There are mainly two types: epoxy AB adhesives and acrylic AB adhesives. For epoxy AB adhesives, the working time can be as fast as 5 minutes at the shortest, and as long as more than half an hour at the slowest. There are quite a lot of choices for the curing time, and they are odorless or have a very low odor. However, after curing, they are hard but rather brittle, and their shock and vibration resistance performance is relatively poor.

On the other hand, acrylic AB adhesives have a relatively fast positioning time. Most of them can complete the positioning within 3 to 5 minutes, so the working time is relatively short. Moreover, acrylic AB adhesives have a relatively strong odor, but their shock and vibration resistance performance is better than that of epoxy AB adhesives. In addition, the temperature resistance performance of epoxy AB adhesives is better than that of acrylic AB adhesives, and they can withstand a high temperature of up to 280 degrees Celsius.

For the bonding of large-area metal plates, Juli’s resin-type metal adhesive with a controllable curing time, model JL-6218, can be used. It is transparent and of high concentration, with good initial adhesion. It can be applied vertically. The initial setting time is 5 to 8 minutes. It is often used for bonding large-area steel plates to steel plates, steel plates to other metal plates, and sheets. Generally, for resin-type metal adhesives, both surfaces need to be coated with the adhesive, and then left to dry until it is no longer sticky to the touch before bonding. However, the JL-6218 metal adhesive has excellent initial adhesion, and it will not fall off even if the two surfaces are bonded immediately after applying the adhesive. After curing, the adhesive film is soft and elastic, has a certain degree of sealing property, and has excellent impact resistance and vibration resistance.